Cost-Effective Temperature Control Solutions for Cold Storage

Temperature control inside cold storage makes sure products that can be perishable as well as lifesaving medications remain effective and potent. Additionally, it helps companies save cash on their energy bills.

Clothing and equipment are essential for workplace safety during colder months. For instance, electric forklift batteries lose energy much more quickly when warehouses are cold due to condensation.

Energy-efficient refrigeration systems

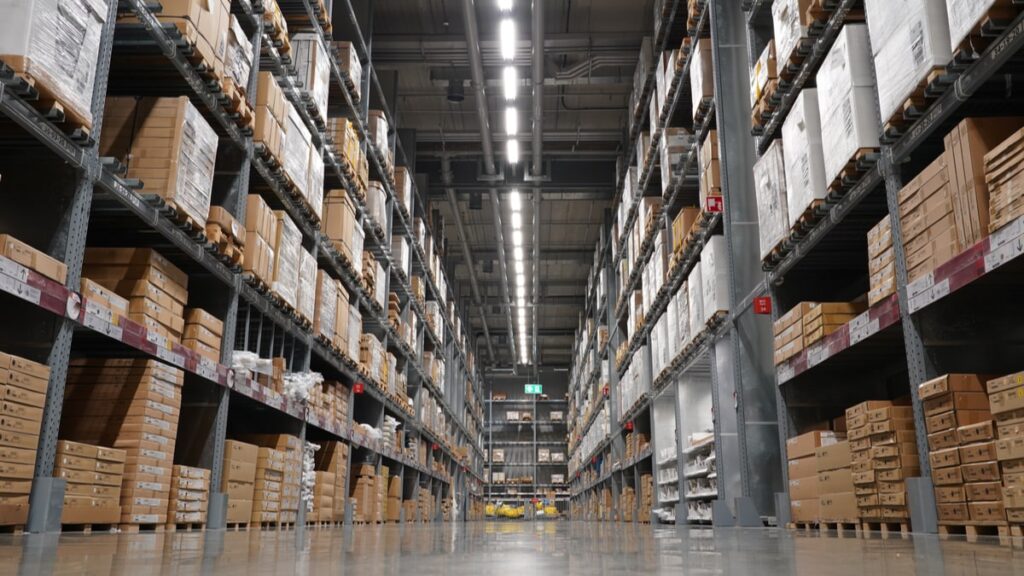

The items stored in cold storage warehouses are susceptible to fluctuations in temperature. The warehouses typically have cooling systems to lessen the chance of. Refrigeration systems work by circulating coolant around to take in heat and reduce its temperature. This cooling technique is used to cool a variety of merchandise, ranging including frozen food items to pharmaceuticals, petrochemicals and electronics.

The refrigeration system that is functioning properly requires periodic inspections and maintenance in order for optimal performance. A routine schedule of checks as well as cleaning could help reduce energy consumption, as well as reduce costs over time.

Smart technology may be employed to monitor energy consumption. Monitoring systems are able to alert businesses to spikes in power usage that could signal a problem with the refrigeration system. They can help optimise consumption of energy by allowing customer to alter the temperature setting according to the requirements of the product. This can lower the workload of refrigeration units by as much as 85% and save lighting energy.

Management of perishable inventory

Management of inventory for perishables needs specific techniques for optimizing supplies chain. Strategies like these can cut down on loss, reduce stockouts and increase customer satisfaction.

Utilizing demand forecasting software and sales analytics to predict changes in inventory levels is a option to increase the efficiency of managing cold storage. This method helps you to schedule your purchasing process to ensure you will have time to store, receive, and sell products before they expire.

Other methods of managing the inventory that is perishable is to choose trusted suppliers who value freshness. Offer favorable terms, negotiate deals as well as conduct checks prior to receipts. This can dramatically improve the quality of your products and in turn, enhance the freshness of finished products.

Another perishable goods inventory strategy is first expiring, last out (FEFO). This method focuses on the use of items that have close date expiration, thus reducing the waste of products. The last but not least is that by regularly establishing the reorder level, you will be able to set an inventory level that meets demands of the customer while eliminating wasted product.

Storage maintenance for cold storage best practices

A variety of products from the food industry as well as pharmaceuticals require certain temperature requirements for storage. The fluctuations in temperature can cause harm to the products and can increase the cost of storage. Maintaining cold storage warehouses with best practices can prevent these issues from occurring.

These goals can be achieved through the improvement of equipment and processes and will lead to large savings in the long run. Good practices include automating processes as well as limiting heat exchange, and making use of equipment designed for cold climates.

It’s also important to take into consideration how your employees will access your cold storage area. If you provide employees with safety apparel and gear which reduces hazards to health while boosting efficiency. Additionally, lap dat kho lanh thuc pham nha hang selecting access systems that can be opened and closed quickly prevents temperature variations as people travel around the workplace. The doors with insulation, such as those, give faster access to different areas and create a seal which limits the air flow between openings. This method reduces maintenance time and improves energy efficiency.

IoT to measure temperature

An essential step for ensuring security of medicines and food is to maintain a consistent temperature within your storage facility. Monitoring devices that use IoT will monitor the temperature in your warehouse all day long, triggering alerts when temperatures exceed pre-set thresholds. This can reduce the amount of time your team spends doing the manual tracking of temperatures while also increasing the quality and accuracy of the temperature logs.

Smart IoT sensors are able to reduce energy consumption and the amount of waste. Through monitoring the performance of equipment and fixing issues quickly and efficiently, you will reduce the requirement for expensive jet fuel and diesel to power refrigeration systems as well as ensure consistent product quality. Temperature data that is real-time can allow you to optimize storage space, reducing the need for unnecessary backups as well as avoiding temperature swings. Find out more about how IoT transforms logistics in the cold chain by combining advanced technology with real-time monitoring and supply chain software.