The Future of Beverage Packaging – Can Packaging Machines Leading the Way

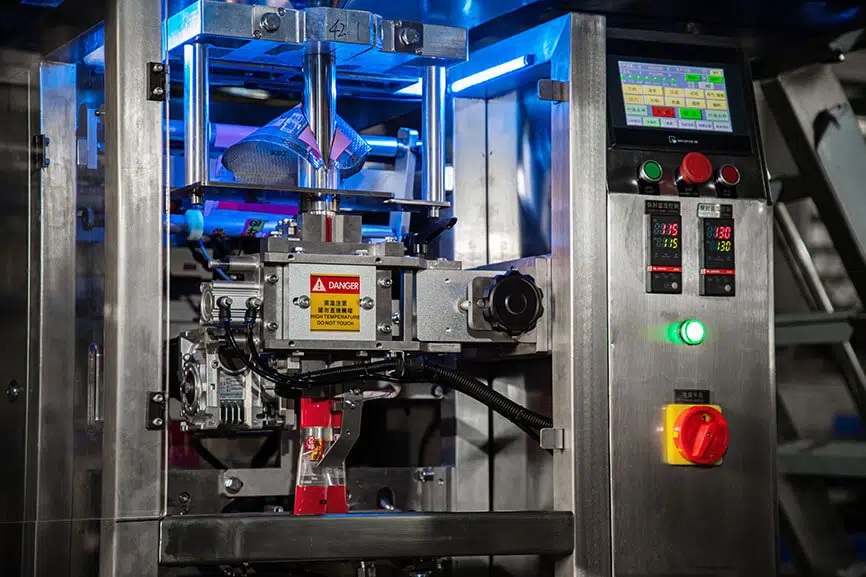

In recent years, the beverage packaging industry has undergone significant transformations, driven by technological advancements and shifting consumer preferences. Central to these changes are packaging machines, which play a crucial role in enhancing efficiency, sustainability, and innovation within the sector. Packaging machines have revolutionized the beverage industry by automating repetitive tasks and streamlining production processes. Advanced technologies such as robotic arms and automated filling systems have significantly increased operational efficiency, reducing labor costs and minimizing human error. This shift towards automation not only accelerates production rates but also ensures consistency in packaging quality, meeting stringent industry standards.

Sustainability and Eco-Friendly Solutions

One of the most pressing challenges facing the beverage packaging industry is sustainability. Packaging machines are at the forefront of this issue, driving the adoption of eco-friendly materials and reducing environmental impact. Innovations like lightweight packaging materials, biodegradable plastics, and recyclable packaging solutions are being integrated into machine designs to meet growing consumer demands for sustainability. Moreover, packaging machines are designed to optimize material usage, minimize waste generation, and improve recycling processes.

Customization and Consumer Engagement

In an increasingly competitive market, beverage companies are leveraging can sealer machines to differentiate their products through customization and enhanced consumer engagement. Advanced printing technologies allow for personalized packaging designs, promotional messages, and interactive features that resonate with target audiences. Packaging machines enable flexibility in packaging sizes, shapes, and functionalities, catering to diverse consumer preferences and market trends. Whether it is offering single-serve options or multipack configurations, manufacturers can adapt quickly to changing consumer behaviors and capitalize on emerging opportunities.

Innovative Materials and Design

The evolution of packaging machines has spurred innovation in materials and design, paving the way for novel packaging formats and enhanced product protection. Barrier technologies and modified atmosphere packaging MAP systems extend the shelf life of beverages, preserving freshness and flavor while reducing the need for additives and preservatives. Furthermore, smart packaging solutions equipped with sensors and RFID tags enable real-time tracking of product quality and supply chain logistics. This integration of technology not only enhances operational efficiency but also ensures product safety and traceability from production to consumption.

Challenges and Future Outlook

Despite the numerous benefits, challenges such as initial investment costs, technological integration, and regulatory compliance remain significant considerations for beverage manufacturers adopting packaging machines. However, ongoing research and development are expected to address these challenges, driving further innovation and market expansion. Looking ahead, the future of beverage packaging machines lies in continued advancements in automation, sustainability, and consumer-centric solutions. As technology evolves, so too will the capabilities of packaging machines, shaping the industry’s ability to meet evolving consumer expectations and regulatory requirements and learn more here now www.levapack.com.

Packaging machines are pivotal to the future of beverage packaging, driving efficiency, sustainability, and innovation across the industry. By embracing technological advancements and consumer insights, beverage manufacturers can navigate challenges and capitalize on opportunities in a dynamic and competitive market landscape.